Cogeneration Plants and Expanders

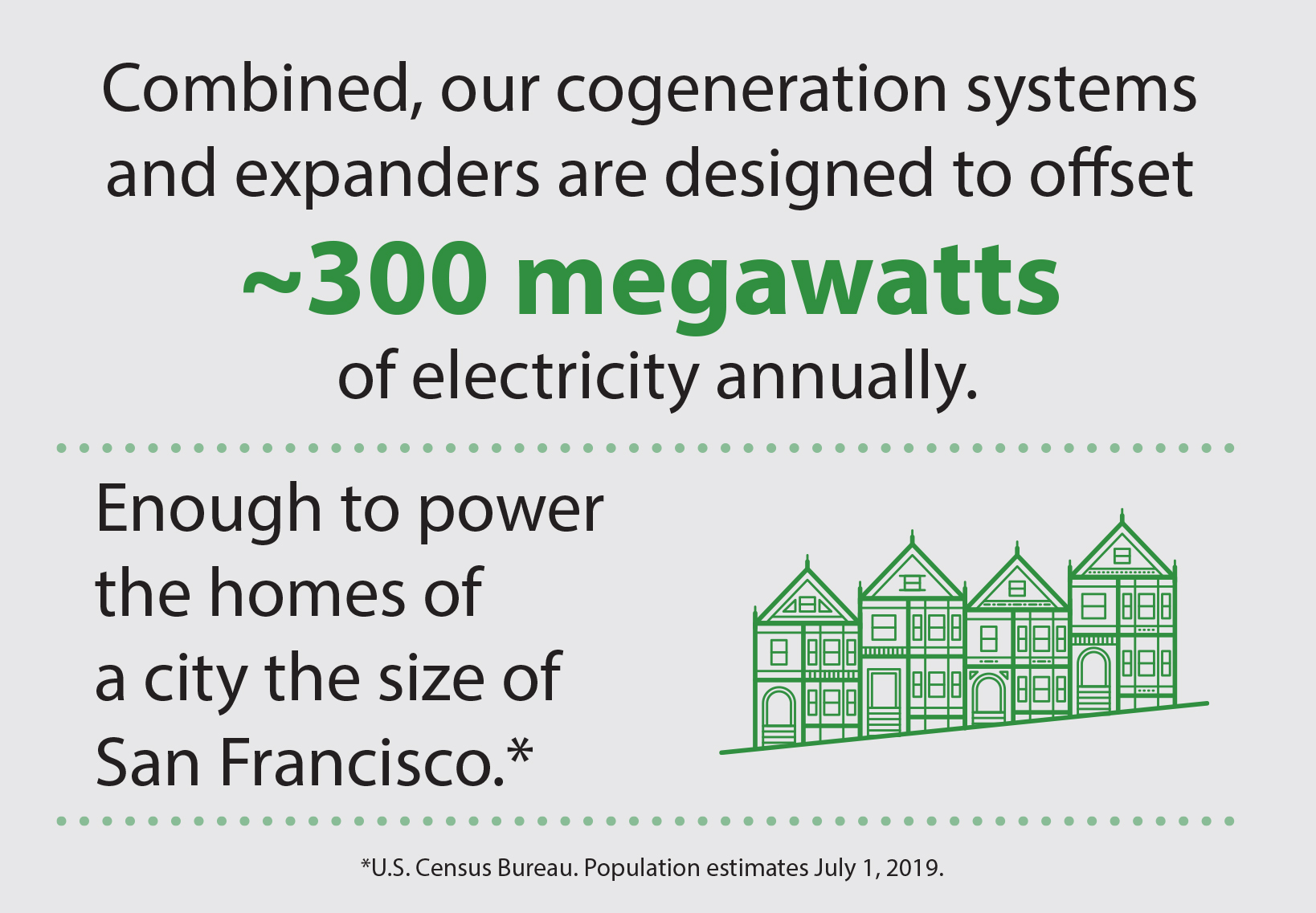

- Cogeneration Plants: Our cogeneration plants reduce our dependency on local power grids, which are often more costly. Cogeneration is a highly efficient and reliable way of producing electricity and thermal energy or steam, with the steam recycled back into the refining process for other uses. Valero has cogeneration systems at refineries in Wilmington, Benicia, Port Arthur and Pembroke.

- Expanders: At six of our refineries, we have installed “expanders” on processing units that generate power from exhaust gases. We have the world’s largest expander at our Corpus Christi West refinery. In all, our expanders are designed with the capacity to annually displace more than 600,000 tons of carbon dioxide that otherwise would be generated by conventional power plants.

Off

Wind Power

Adjacent to our McKee refinery in the Texas Panhandle, our wind farm includes 33 wind turbines with 50 megawatts of power generation capacity.

Off

Hydropower

More than 99% of the electricity used at our Quebec City refinery comes from renewable sources – mainly hydropower, with small portions from wind, biomass, nuclear and thermal.

What Fuels Us We care about the environment, our employees and the communities where we work and live.

Responsibility

Waste Management

Responsibility

Recycling Process

Responsibility