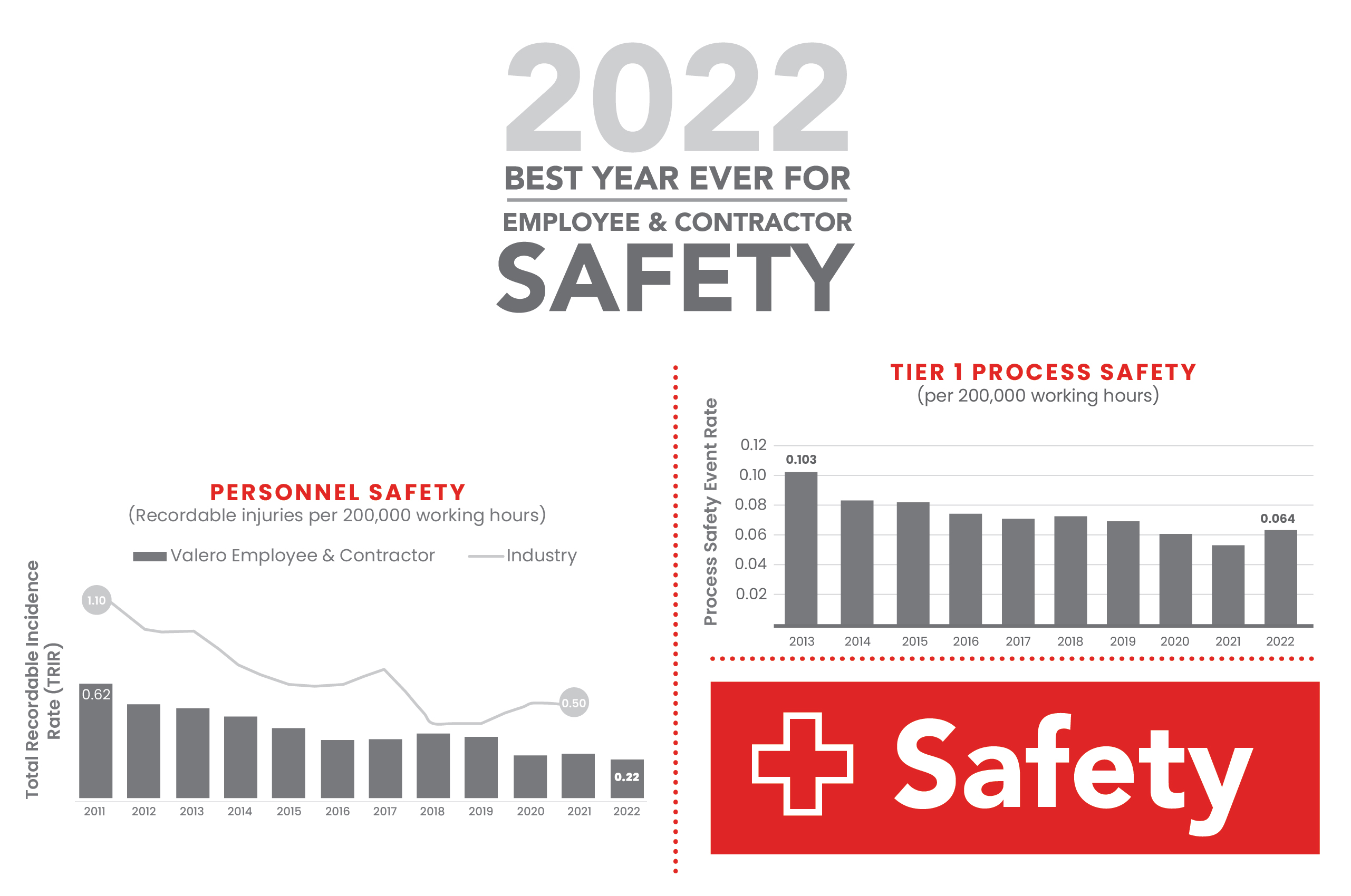

At Valero, we believe that safety and reliability are important, not only for the protection of our employees and communities, and the cultural values we aspire to as a company, but also for operational success. A decrease in the number of employee and process safety events should generally reduce unplanned shutdowns and increase the operational reliability of our refineries and plants.

This, in turn, should also translate into a safer workplace with fewer environmental incidents and stronger community relations.

We strive to improve safety and reliability performance by offering year-round safety training programs for our employees and contractors, and by seeking to promote the same expectations and culture of safety.

We also seek to enhance our safety performance by conducting safety audits, quality assurance visits, and comprehensive safety and risk assessments at our facilities.

Beyond Compliance: Leading the Way for Voluntary Protection

Our participation in the U.S. Department of Labor Occupational Safety and Health Administration's (OSHA) Voluntary Protection Program (VPP) exemplifies our consistent pursuit of going beyond regulatory requirements by voluntarily submitting to robust safety audits. OSHA approves VPP Star Site status only if the facility demonstrates that enhanced safety systems have been implemented and embraced in a collaborative way by leaders and employees. Sites are reassessed by OSHA every three to five years in order to maintain their VPP status.

Safety Excellence

At Valero, the safety of our employees, contractors and communities is of utmost importance. Our robust safety initiatives, year-round training programs and extensive safety management systems all contribute to our goal of safety excellence.

Environment

We have made multibillion-dollar capital investments to sustain our operations as part of our commitment to safety, reliability, preventive equipment maintenance and environmentally responsible operations for our refineries. We have formal processes and monitoring systems designed to protect our people, our communities and the environment. We initiate mitigation actions when environmental events are identified.

Process Safety and Reliability

Our process safety and reliability programs proactively contribute to our goal of operational excellence.

These programs provide safeguards for certifying our equipment is correctly designed, regularly maintained and safely operated. Valero employs an industry-leading technical process safety and reliability assessment program to drive first-quartile reliability performance and help maintain the safety of our employees and communities. We continue to evaluate and utilize state-of-the-art process control and equipment monitoring technology to optimize operations efficiency.

Emergency Preparedness

and Response

With refineries along coastlines and ethanol plants in the U.S. Midwest, Valero has long evaluated and prepared for physical risks to its facilities from natural disasters and weather events. Our emergency preparedness and response programs are focused on the mitigation of these risks.

Check out our Report on Guiding Principles for additional information on Valero’s emergency response programs.

Emergency Management Planning Our company-wide emergency management process is designed to assess potential risks posed to our people and operations and implement solutions.

- Emergency response plans at each facility that comply with all local, state and federal regulations and are regularly updated with third-party assessments to ensure excellence.

- Confirming equipment and facilities are maintained in fully functional condition and are readily available along with trained personnel when needed for emergency response.

- Ensuring qualified emergency response teams with strong relationships with third-party response personnel are present on-site.

- Performing regular drills and assessments to promote response readiness and alignment with our Goal Zero program.

- Allocating capital resources to emergency planning and response in the strategic planning and capital budget processes to make our facilities efficient and resilient.

- Employing the use of emerging technologies to optimize decision-making and response execution.

STAR Metric

The STAR (Safety Tracking and Recognition) Metric is our safety program for our ethanol plants. This program recognizes top performing ethanol plants in five key areas:

- Process Safety

- Reliability

- Environmental

- Rail Safety

- Policy and Procedure Compliance

Each quarter we recognize plants achieving zero incidents in all five areas. Plants that go four consecutive quarters without an incident earn a Super STAR award.

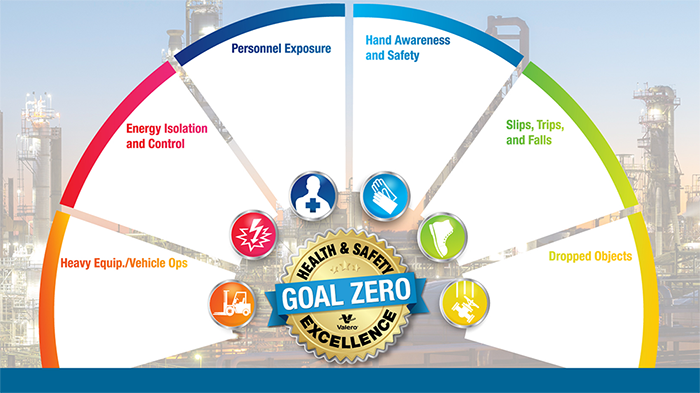

Goal Zero Safety Program

Our Goal Zero program is designed to eliminate incidents and injuries in six focus areas by taking a data-driven risk-based approach.

Goal Zero Safety Program

Our Goal Zero program is designed to eliminate incidents and injuries in six focus areas by taking a data-driven risk based approach:

Life-Saving Rules To ensure full compliance with our safety policies and procedures, Valero implemented Life-Saving Rules – seven, long-standing critical rules that must be followed at all times:

- Work with a valid permit when required

- Verify energy isolation before beginning work

- Obtain authorization before entering a confined space

- Obtain authorization before overriding or bypassing a safety system

- Use specified life-protection equipment

- Protect yourself against a fall when working at heights

- Smoke in designated smoking areas only

Safety Data Sheets

Safety data sheets provide, in a standard format, product safe use and handling information regarding potential hazards, and how to respond to emergencies.

Safety Stories

Safety is integrated into every aspect of what we do at Valero. We instill safety and reliability at every facility to push beyond regulatory compliance to operational excellence.

Protecting Our Environment and Our Neighbors We hold ourselves to the highest standards of safety, responsible operations, and care about the environment, our employees, and our communities.

Environment