Ethanol Science & Process

The Technical Side of

Ethanol Production

Valero's 12 state-of-the-art ethanol plants produce ethanol and other valuable products from field corn.

Valero's 12 state-of-the-art ethanol plants produce ethanol and other valuable products from field corn.

Local farmers and suppliers deliver field corn to our plants by truck and rail.

Water, yeast and enzymes are mixed and heated to form corn mash, which is allowed to ferment to produce ethanol.

The fermented mash is heated to separate the ethanol from the water and solids in distillation.

The non-fermentable solids are dried to produce the feed product – distillers grains.

Ethanol is shipped primarily by rail to fuel providers who mix the ethanol with gasoline to be sold at Valero stations and other fuel outlets.

Distillers grains are shipped primarily by truck, rail and barge to businesses that process them into livestock feed. The corn oil is shipped primarily to plants to make renewable diesel fuel.

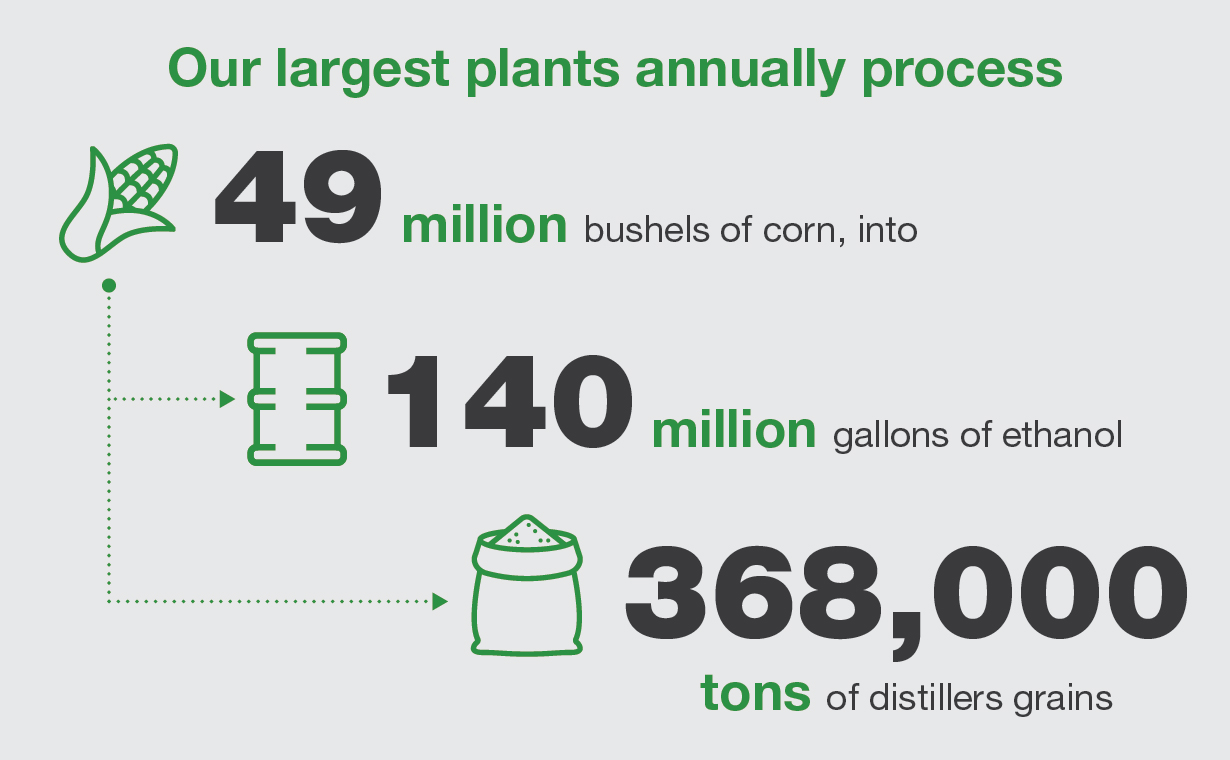

Production Capacity at Our Largest Plants

Our largest plants annually process 57 million bushels of corn into 140 million gallons of ethanol and 434,000 tons of distillers grains.

Ethanol is a clear liquid that is blended with gasoline, improving combustion that releases the energy to power the car’s engine.

Ethanol lowers life cycle greenhouse gas emissions at least 30% compared to non-blended gasoline.

Ethanol is made from field corn, which typically is used for livestock feed and industrial use. The kind of corn we eat is called sweet corn. Only 1 percent of corn grown in the U.S. is sweet corn for human consumption. The remainder is field corn used for livestock feed and fuels.

Each year we use approximately 583 million bushels of corn, to supply our ethanol plants.

Processing corn results in ethanol, distillers grains and fuel- and feed-grade corn oil.

Distillers grains are the co-product from the fermenting process, consisting of protein, fat, fiber and other solids. These can be dried or modified (partially dried).

Because of its concentration of nutrients, distillers grains are a valuable livestock feed for cattle, swine and poultry.

Modern Plants

All our ethanol plants have been built in the last 25 years and use state-of-the-art technology and modern control systems. We are a leader in the industry in reliability, production efficiency and energy efficiency.